Spirit of Dingle Coming Soon.

On the 18th of December 2012, a week before Christmas, the Dingle Distillery started making whiskey. You may well see the results around this Christmas, as the whiskey has now served more than the necessary three years and one day in 700 litre capacity oak barrels. The period time, the oak and the barrel size are all mandatory, we were told on a tour during last weekend’s Dingle Food Festival.

On the 18th of December 2012, a week before Christmas, the Dingle Distillery started making whiskey. You may well see the results around this Christmas, as the whiskey has now served more than the necessary three years and one day in 700 litre capacity oak barrels. The period time, the oak and the barrel size are all mandatory, we were told on a tour during last weekend’s Dingle Food Festival.

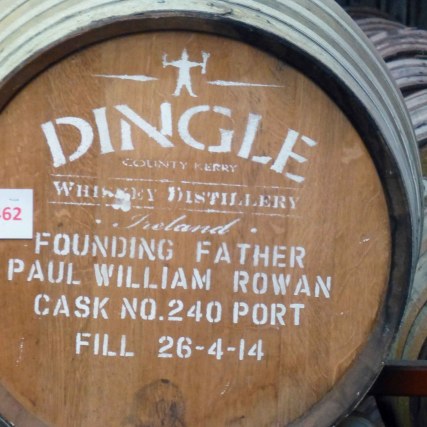

It looks as if it may be a Happy Christmas for Dingle and for the “Founding Fathers”. These pioneers could also be called the Funding Fathers as it was their money that got the project off the ground, each offering up about six thousand euro for a cask in his or her own name. We saw quite a few of the barrels during the tour and there is also a founding fathers’ wall with all the names inscribed.

The Spirit of Dingle, with the mouth of the harbour featured, is the name of a painting by a local artist that inspired the setting up of the distillery. And that view can be seen from the gates of the distillery which stands on the western edge of the town.

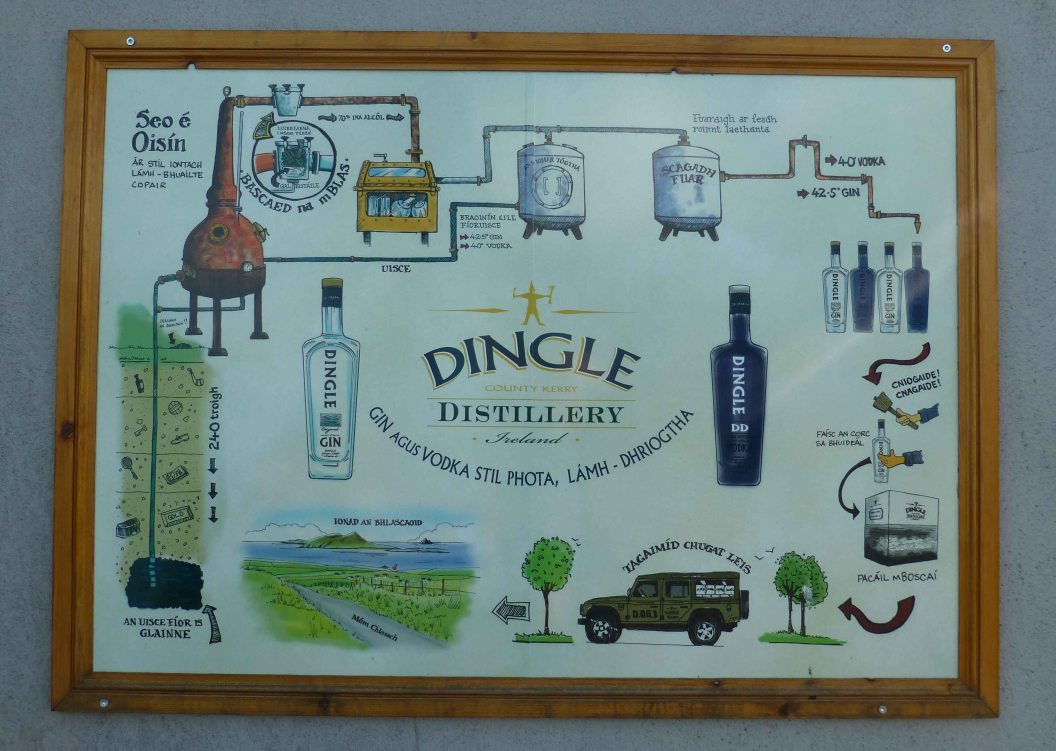

Like all whiskeys, Dingle’s goes through three main stages: fermentation, distillation and maturation. Yeast is added during fermentation and when it sinks to the bottom, that is the end of the fermentation (see timber fermentation vessels in 2x pic slideshow at bottom). By the way, if you can manage a sniff of a vessel when the yeast is active, it is a great way to clear a stuffy nose! Just don’t overdo it – it is potent!

At end of fermentation, the incipient whiskey has an abv of about 10 % , much like a very strong beer. By the end of the next stage the distilling, the abv has risen to 80 or 85%. It is “cut” with water later to bring the strength down to the normal 40%.

The process in Dingle though is distinguished by the use of a boil bowl on two of the copper stills. This gives what you need for nice, smooth spirit: plenty of reflux. This built-in bulge (see 2 x pic slide show below) in the neck – other stills have long slim necks – means the vapour doesn’t all rise right up and condense beyond the drop. You need it to condense and fall back into the still a few times before it eventually condenses and drips into the receiver. And so, to get this smooth spirit before maturation, was why Dingle modified their still design.

I didn’t know that barrels used for the maturation of Irish whiskey had to be a certain size but I did know that the barrels have already been used elsewhere, “secondhand” as our guide Shane termed it. The barrels used most in Dingle have previously held Bourbon, Port, and Sherry. By the way, there is a constant evaporation during maturation, the often quoted Angels’ Share.

Shane then showed us a smaller area where their gin and vodka are produced in a much simpler way, though the gin process “is a little bit more difficult”. Interestingly, Dingle uses no less than 13 botanicals in their very popular gin. All the bottling is done on site.

And the site has been in use, on and off, since 1840 when it started life as a flour mill. I spotted an old mill-wheel in storage. A fire destroyed this first business and later, in 1914, a lumber firm took over.

We were then taken to the tasting room and introduced to the main ingredients: malted barley, milled barley and yeast. Here, we enjoyed a taste of the vodka and the gin. No whiskey to taste, of course, but we did get a drop of the “raw spirit” with an abv of about 65%. Hot stuff, yet it tasted quite smooth – “a good sign” said Shane.

Good things to come, then, from those whiskey casks. All at Dingle and, indeed a wider audience, are looking forward to the day in the very near future when Cask No. 2 is opened. (Cask No. 1 will be kept closed in perpetuity!). Happy Christmas with the spirit of Dingle!

See also: Driving the Dingle Peninsula

Dingle and its massive Food Festival

See also: Driving the Dingle Peninsula

Dingle and its massive Food Festival

No comments:

Post a Comment